Mokhoa oa Tlhahiso ea Margarine

Mokhoa oa Tlhahiso ea Margarine

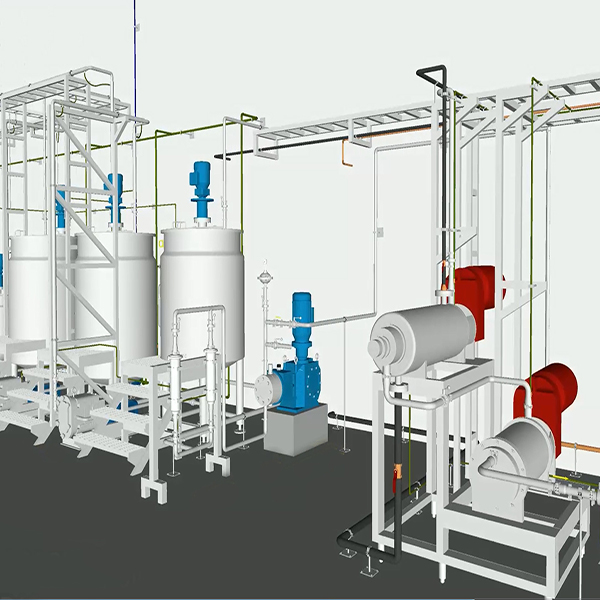

Tlhahiso ea margarine e kenyelletsa likarolo tse peli: ho lokisa thepa e tala le ho pholisa le ho etsa polasetiki. Lisebelisoa tse ka sehloohong li kenyelletsa litanka tsa ho lokisa, pompo ea HP, votator (mochine o chesang holim'a mocheso), mochini oa rotor oa pin, yuniti ea sehatsetsi, mochini o tlatsang margarine joalo-joalo.

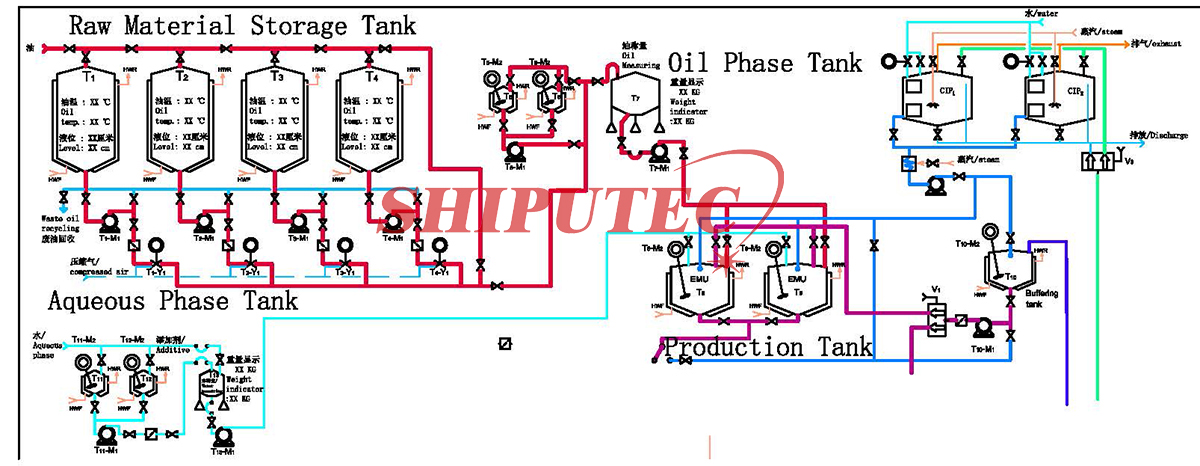

Ts'ebetso ea pele ke motsoako oa karolo ea oli le karolo ea metsi, tekanyo le motsoako oa emulsification oa karolo ea oli le karolo ea metsi, e le ho lokisa lijo tsa thepa bakeng sa ts'ebetso ea morao-rao. Mokhoa oa ho qetela ke ho pholile ka ho tsoelang pele ka polasetiki le ho paka lihlahisoa.

Mokhoa oa ho lokisa thepa e tala ea margarine e bontšoa ho Setšoantšo sa 1:

- 1.Lebese le lomositsoeng

Ba bang ba majarine foromo ho eketsa lebese, 'me lebese ka mor'a hore lactic acid libaktheria fermentation ka hlahisa tatso e tšoanang ea tranelate ea tlhaho, kahoo fektheri ho lebese lomositsoeng le metsi a tsoakiloeng.

- 2.Ho kopanya metsi

Li-additives tse qhibilihang ka metsing le metsi ka mokhoa oa margarine, joalo ka lebese le lomositsoeng, letsoai, li-preservative, joalo-joalo, li ekeletsoa ho motsoako oa metsi le tanka ea metering ka tekanyo e behiloeng ea ho hlohlelletsa le ho kopanya, e le hore karolo ea metsi. likarolo li qhibiliha ka tharollo e ts'oanang.

- 3.Mokhahlelo oa oli ho kopanya

Oli e tala ea litlhaloso tse fapaneng e qala ka ho kopanngoa ka tanka ea ho kopanya oli ho ea ka tekanyo e behiloeng, ebe li-additives tse qhibilihang ka oli, tse kang emulsifier, antioxidant, pigment e qhibilihang ka oli, selulose e qhibilihang ka oli, joalo-joalo, e kenngoa ho karolo ea oli ho ea ka tekanyo, e kopantsoeng le tanka ea metering, 'me e tsosoa ho etsa karolo e tšoanang ea oli.

- 4.Emulsion

Sepheo sa emulsification sa margarine ke ho etsa hore karolo ea metsi e be ka tsela e ts'oanang le e tsitsitseng e qhalakantsoeng karolong ea oli, 'me tekanyo ea ho hasana ea karolo ea metsi e na le tšusumetso e kholo ho boleng ba sehlahisoa. Hobane tatso ea margarine e amana haufi-ufi le boholo ba likaroloana tsa karolo ea metsi, ho ata ha likokoana-hloko ho etsoa karolong ea metsi, boholo ba libaktheria tse akaretsang ke 1-5 microns, kahoo marotholi a metsi a 10-20. li-micron kapa mefuta e fokolang e ka fokotsa ho ata ha libaktheria, kahoo ho hasana ha metsi ho molemo haholo, likaroloana tsa karolo ea metsi li nyenyane haholo li tla etsa hore margarine e lahleheloe ke tatso; Ho qhalakanngoa ha hoa lekana, karolo ea karolo ea metsi e kholo haholo, e tla etsa hore margarine e silafatse metamorphism. Kamano lipakeng tsa tekanyo ea phallo ea metsi ka har'a majarine le mofuta oa sehlahisoa e batla e le ka tsela e latelang:

| 水滴直径 Lerotholi la metsi (微米 micrometer) | 人造奶油性质 (Taste of Margarine) |

| ka tlase ho 1 (hoo e ka bang 80-85% ea karolo ea metsi) | Tatso e boima le e fokolang |

| 30-40 (ka tlase ho 1% ea karolo ea metsi) | Tatso e ntle, e bonolo ho bolisoa |

| 1-5 (hoo e ka bang 95% ea karolo ea metsi) | Tatso e ntle, ha ho bonolo ho e senya |

| 5-10 (hoo e ka bang 4% ea karolo ea metsi) | |

| 10-20 (hoo e ka bang 1% ea karolo ea metsi) |

Ho ka bonoa hore ts'ebetso ea emulsification e lokela ho fihlela tekanyo e itseng ea litlhoko tsa ho hasana.

Sepheo sa ho kopanya karolo ea metsi le karolo ea oli ka ho arohana le ka mokhoa o ts'oanang le mohato oa pele ke ho etsa bonnete ba ho ts'oara ho ts'oanang ha emulsion eohle ka mor'a hore ho be le emulsification le ho kopanya oli le metsi mekhahlelo e 'meli. Ho kopanya emulsification ke hore, bothata ba ts'ebetso ke likhato tse 50-60, karolo ea metsi e eketsoa karolong ea oli e lekantsoeng, ka mochine o susumetsang kapa oa pompo o susumetsang, ke karolo ea metsi e qhalakantsoeng ka ho feletseng karolong ea oli, ho thehoa ha latex. Empa mofuta ona oa mokelikeli latex haholo sa tsitsang, khaotsa ho susumetsang maikutlo ka 'na ba ka lebaleng la lipapali oli le metsi karohano phenomenon.

Ka mor'a hore emulsion e tsoakiloeng e fanoe, mokhoa oa ho pholile le oa polasetiki o etsoa ho fihlela sehlahisoa se kenngoa.

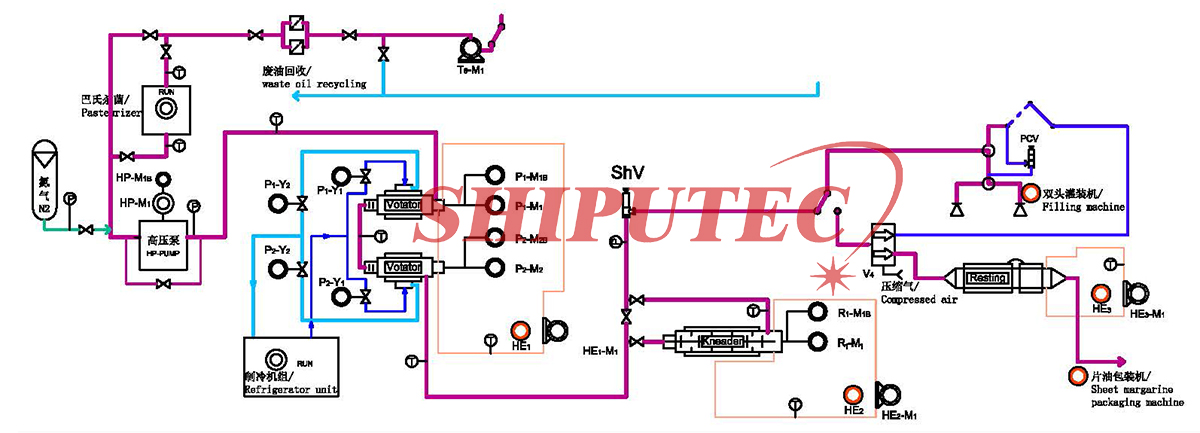

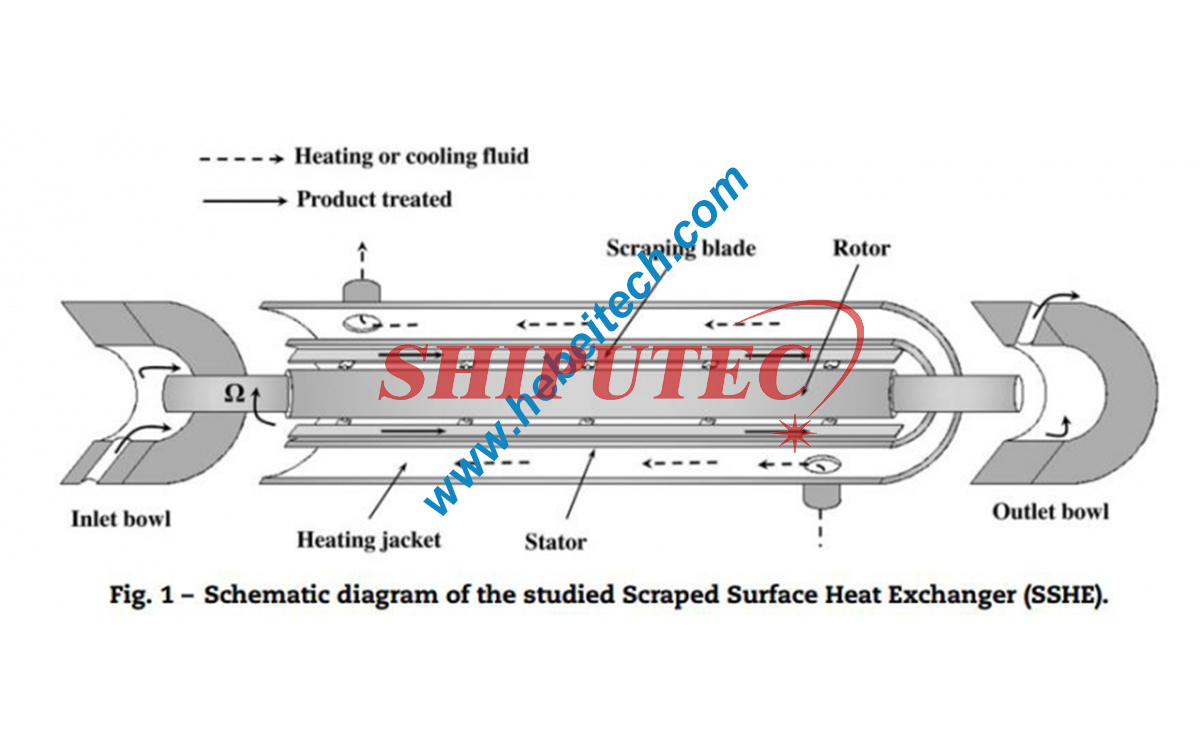

Emulsion e tlameha ho pholile le ho etsoa polasetiki ho hlahisa sehlahisoa sa margarine se tenyetsehang. Hajoale, e sebelisa sesebelisoa sa ho tima polasetiki se koetsoeng, ho kenyeletsoa votator kapa se bitsoang scraped surface heat exchanger (unit A), mochini oa rotor kapa mochini oa ho luba (yuniti C) le pompo ea ho phomola (yuniti ea B). Ts'ebetso ea thekenoloji e bontšoa ho Setšoantšo sa 2:

Sehlopha sena sa lisebelisoa se na le litšobotsi tse latelang:

1. Tšebetso e tsoelang pele ea khatello e phahameng ea khatello e sa keneleng moea

Emulsion ea premixed e kenngoa ka har'a silindara ea ho tima ka pompo ea khatello e phahameng bakeng sa movota. Khatello e phahameng e ka hlōla khanyetso ho pholletsa le yuniti, ho phaella ts'ebetsong ea khatello e phahameng e ka etsa hore sehlahisoa se be se tšesaane le se boreleli. Ts'ebetso e koetsoeng e ka thibela moea le moea ka lebaka la ho tima le condensation ea metsi a kopantsoeng le emulsion, ho netefatsa litlhoko tsa bophelo bo botle ba sehlahisoa, ho fokotsa tahlehelo ea sehatsetsing.

2. Ho tima le ho etsa emulsification

Emulsion e tingoa ka ammonia kapa Freon ho vouta ho pholisa emulsion ka potlako, e le hore ho hlahisoe likaroloana tse nyenyane tsa kristale, ka kakaretso li-microns tse 1-5, e le hore tatso e be bonolo. Ho phaella moo, scraper ka shaft e potolohang ka votator e amana haufi-ufi le lerako le ka hare la silinda, kahoo scraper e sebetsang e ke ke ea tsoela pele ho senya kristallise e khomarelang leboteng le ka hare, empa hape e etsa hore emulsion e qhalane ho ea kopana le litlhoko tsa emulsification tsa molumo.

3. Ho duba le ho omisa (motjhini wa rotor)

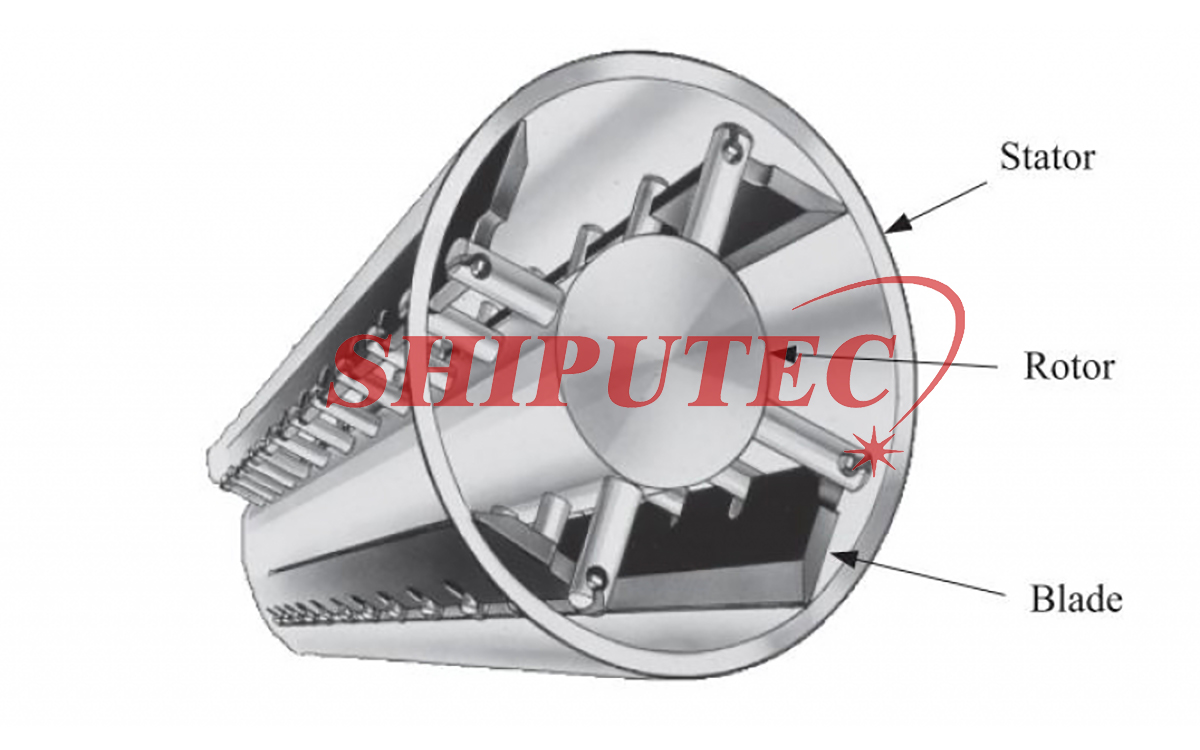

Le hoja emulsion e pholileng ke votator e se e qalile ho hlahisa crystallization, e ntse e hloka ho hōla ka nako e itseng. Haeba emulsion e lumelloa ho khanya ha u phomotse, marang-rang a likristale tse tiileng tsa lipid a tla theha. Phello ke hore emulsion e pholileng e tla theha boima bo thata haholo bo se nang polasetiki. Ka hona, e le hore u fumane lihlahisoa tsa margarine ka polasetiki e itseng, mohaho oa marang-rang o tlameha ho rojoa ka mekhoa ea mechine pele emulsion e etsa sebopeho sa marang-rang ka kakaretso, e le ho finyella phello ea ho fokotsa ho teteaneng. Kneading le de-thickening e etsoa haholo ka mochini oa pin rotor.

Yuniti A (movota) ha e le hantle ke sesebelisoa sa ho pholisa sekhechana. Emulsion e khannoa ka yuniti e koetsoeng A (votator) ka pompo ea khatello e phahameng. Boitsebiso bo feta ka mocha pakeng tsa cylinder e pholileng le shaft e potolohang, 'me mocheso oa thepa o theoha ka potlako ka ho tima mochine o pholileng. Mela e 'meli ea li-scrapers e hlophisitsoe holim'a sefate. Likristale tse entsoeng ka holim'a sebaka se ka hare sa motho ea voutang li hlajoa ke scraper e potolohang ka lebelo le phahameng ho lula e pepesa sebaka se secha sa ho pholile le ho boloka mocheso o sebetsang hantle. Emulsion e ka qhalakanngoa tlas'a ketso ea scraper. Ha thepa e feta ka unit A (votator), mocheso o theohela ho likhato tse 10-20, tse tlase ho feta ntlha ea ho qhibiliha ha oli. Le hoja oli e qala ho phatsima, ha e e-s'o be le boemo bo tiileng. Ka nako ena, emulsion e boemong ba ho pholile 'me ke mokelikeli o teteaneng.

Axis ea potoloho ea unit A (votator) ha e na letho. Nakong ea ts'ebetso, metsi a chesang a likhato tse 50-60 a tšeloa bohareng ba axis ea ho potoloha ho thibela crystallization e kopantsoeng le ho phekoloa holim'a axis le ho baka ho thibela.

Yuniti ea C (mochini oa rotor) ke sesebelisoa sa ho luba le ho holisa, joalo ka ha ho bonts'itsoe setšoantšong se kaholimo. Mela e 'meli ea liboutu tsa tšepe e kenngoa holim'a sefate se potolohang,' me ho kenngoa lerako la liboutu tsa tšepe tse tsitsitseng leboteng le ka hare la silindara, e ts'oarehang ka liboutu tsa tšepe holim'a sekoti 'me ha li amane. Ha sefate se potoloha ka lebelo le phahameng, liboutu tsa tšepe holim'a sekoti li fetisa lekhalo la liboutu tsa tšepe tse tsitsitseng, 'me thepa e kenngoa ka ho feletseng. Tlas'a ketso ena, e ka khothalletsa kholo ea likristale, ea senya sebopeho sa marang-rang sa kristale, ea etsa likristale tse sa khaotseng, ea fokotsa ho tsitsisa, le ho eketsa polasetiki.

Yuniti ea C (mochini oa rotor ea pin) e na le phello e matla ea ho luba bosiu bo batang haholo, ka hona e hloka feela ho boloka mocheso 'me ha e hloke ho pholisoa. Ha mocheso oa crystallization o lokolloa (hoo e ka bang 50KCAL/KG), 'me mocheso o hlahisoang ke ho khohlano ha ho luba, mocheso oa mocheso oa unit C (pin rotor macjhine) o phahame ho feta oa mocheso oa phepelo. Ka nako ena, crystallization e ka ba 70% e feletseng, empa e ntse e le bonolo. Sehlahisoa sa ho qetela se lokolloa ka valve ea extrusion, 'me e tla ba thata ka mor'a nako e itseng.

Ka mor'a hore margarine e rometsoe ho tloha ho C unit (pin rotor machine), e hloka ho phekoloa mocheso ka mocheso o itseng. Ka kakaretso, sehlahisoa se behiloe mocheso oa likhato tse 10 ka tlase ho sebaka se qhibilihang ka lihora tse fetang 48. Kalafo ena e bitsoa ho butsoa. Sehlahisoa se phehiloeng se ka romeloa ka kotloloho setsing sa ho lokisa lijo hore se sebelisoe.